For Contractors

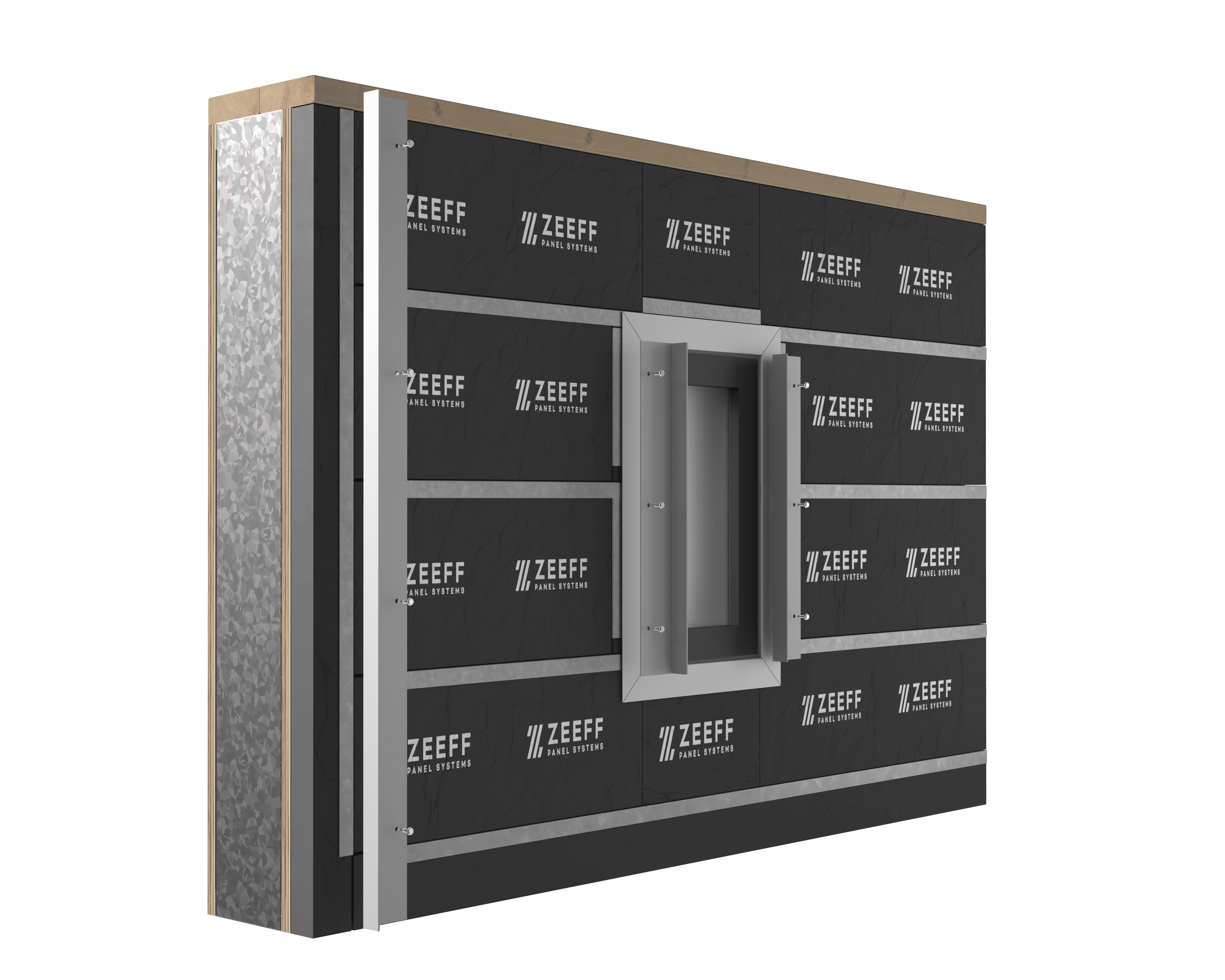

INSTALLATION MADE SIMPLE

Our panel system is engineered for speed and simplicity. Each panel locks securely at the bottom, eliminating the need for extra fastening and reducing labor time. With fasteners required only at the top, installation is cleaner, faster, and more efficient—helping you get the job done with precision and ease..png?width=300&name=Installation%20background%20(1).png)

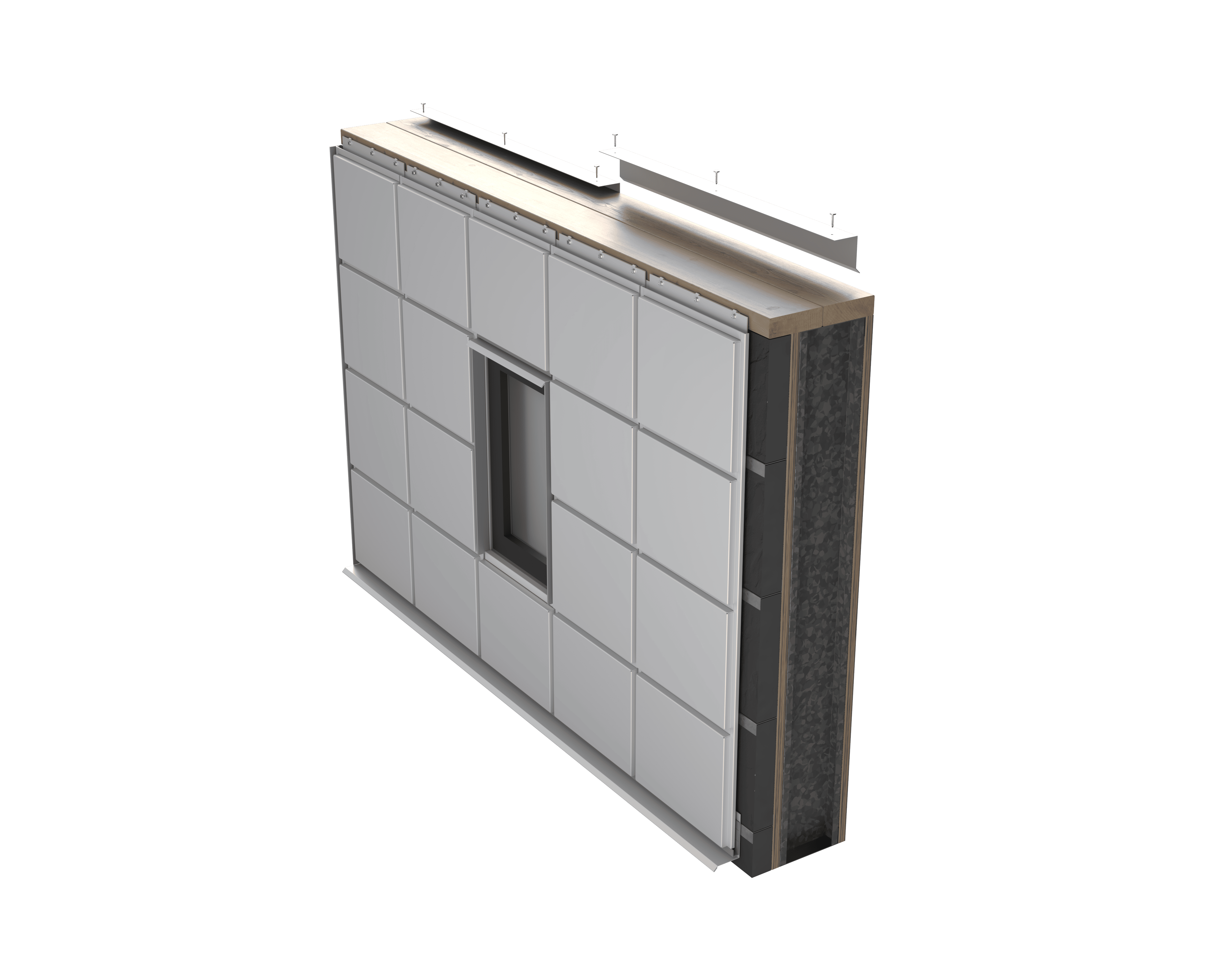

Premier Installation Process

For precise installation requirements and to ensure compliance with project specific conditions, always refer to the approved shop drawings.

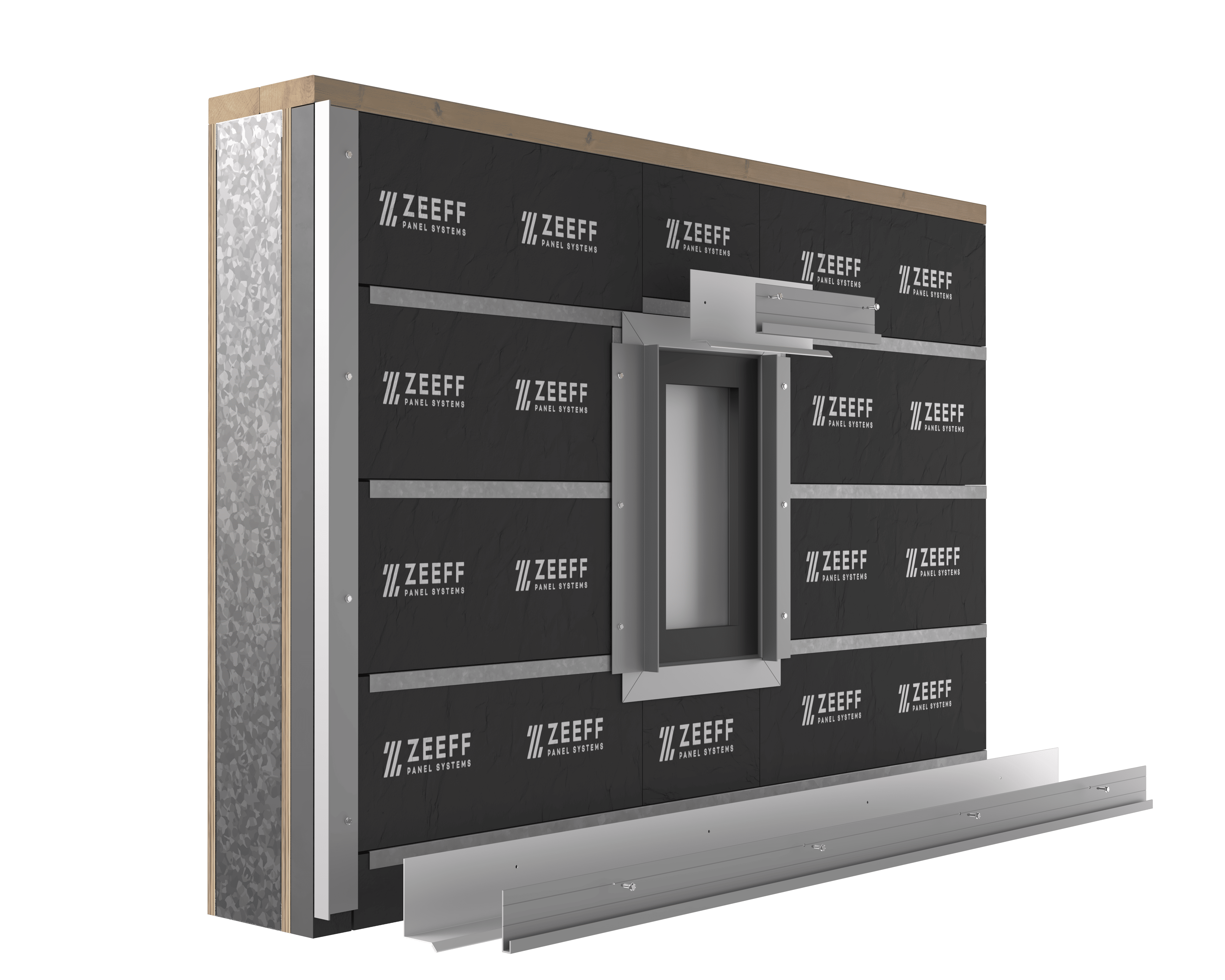

Install the small “J” starter extrusion where bottom panel engagement is needed.

Drill weep holes as needed and fasten it to the bottom of the work area.

Fasten the coping cleat before the installation of the coping cap and splice plate.

During installation, insert the splice plate into the coping cap. For integrated coping, secure it directly into the face of the panel’s J pocket.

ZPS supplies 6in. splice plates when coping is added to a purchase order.

Select Installation Process

For precise installation requirements and to ensure compliance with project specific conditions, always refer to the approved shop drawings.%20(1).png?width=7500&name=1%20(1)%20(1).png)

%20(1).png?width=7500&name=4%20(1)%20(1).png)

Install the 2 piece J extrusion backpiece where needed.

Drill weep holes as need at the bottom.

%20(1).png?width=7500&name=3%20(1)%20(1).png)

%20(1).png?width=7500&name=7%20(1)%20(1).png)

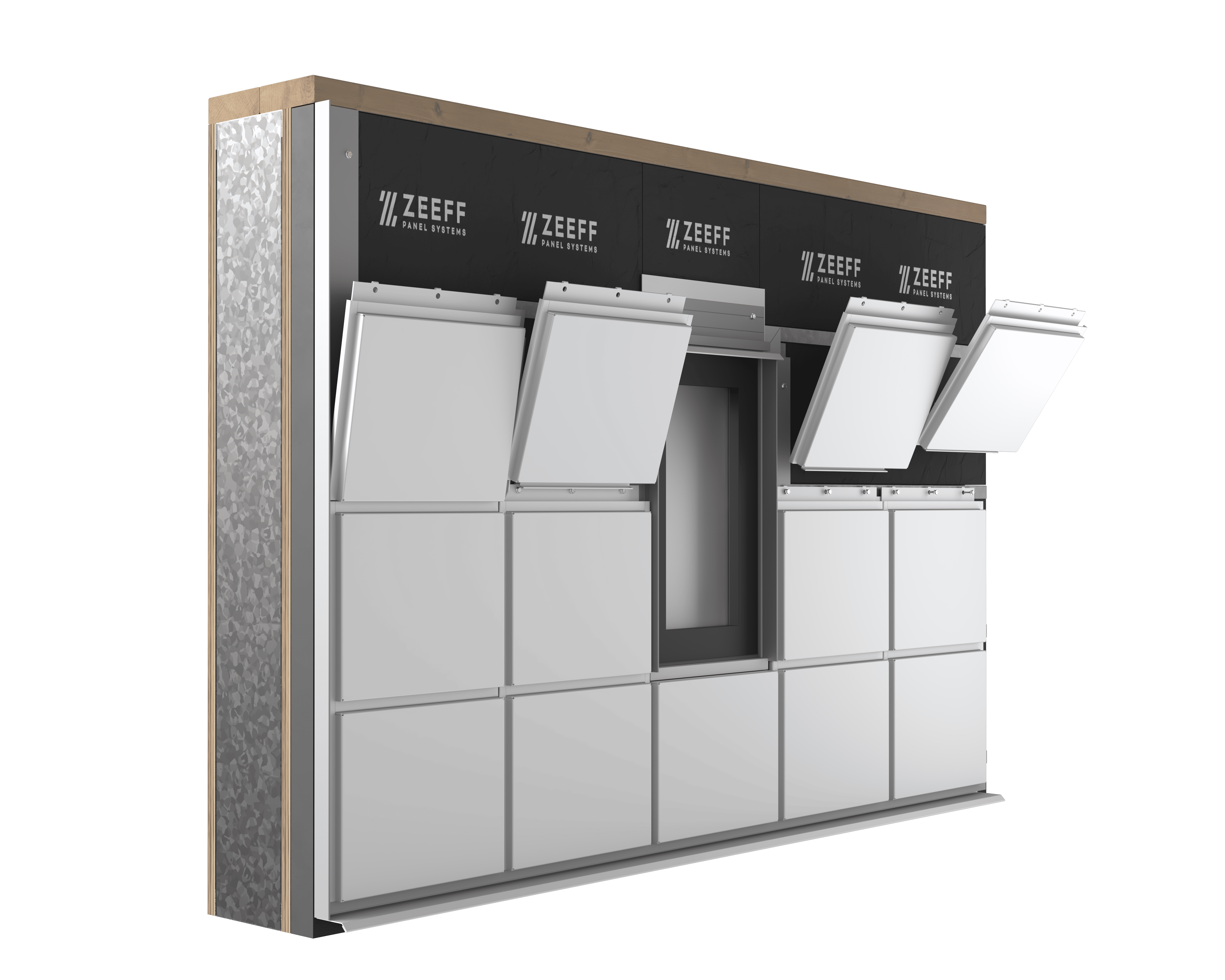

Field trim panels as needed to accommodate site conditions.

Begin installation at the bottom left corner of the assembly.

%20(1).png?width=7500&name=11%20(1)%20(1).png)

%20(1).png?width=7500&name=13%20(2)%20(1).png)

%20(1).png?width=7500&name=14%20(2)%20(1).png)

Panel Parameters & Technical Information

.080" Aluminum

Technical Information

| Material | .080" Post Anodized Aluminum, .080" Post Painted Aluminum |

| System Depth | 1-1/4" nominal standard, Up to 6" |

| Material Weight | Less than 2 lbs. / s |

| Panel Joints | 5/8" nominal (1/8" - 1" available |

| Material Finish | 70% PVDF | 100% FEVE, AAMA 2605 |

| Warranty | 20 years for paint | 2 years for MFG |

.125" Aluminum

Technical Information

| Material | .125" Post Anodized Aluminum, .125" Post Painted Aluminum |

| System Depth | 1-1/2" nominal standard, up to 10" |

| Material Weight | Less than 2 lbs. / s |

| Panel Joints | 5/8" nominal (1/8" - 1" available |

| Material Finish | 70% PVDF | 100% FEVE, AAMA 2605 |

| Warranty | 20 years for paint | 2 years for MFG |

1.0mm NedZink

Technical Information

| Material | 1.0mm Zinc |

| System Depth | 1-1/4" nominal standard, up to 3" |

| Material Weight | ≈ 2 lbs. / sf |

| Panel Joints | 5/8" nominal (1/8" - 1" available) |

| Material Finish | Naturel | Neo | Noir | Nuance |

| Warranty | NedZink - Material, 10 years | 2 years MFG |

1.5mm NedZink

Technical Information

| Material | 1.5mm Zinc |

| System Depth | 1-1/4" nominal standard, up to 3" |

| Material Weight | ≈ 2 lbs. / sf |

| Panel Joints | 5/8" nominal (1/8" - 1" available) |

| Material Finish | Naturel | Neo | Noir | Nuance |

| Warranty | NedZink - Material, 10 years | 2 years MFG |

18GA Weathering Steel

Technical Information

| Material | 18 GA | A606-4 Weathering Steel |

| System Depth | 1-1/4" nominal standard, up to 3" |

| Material Weight | ≈ 3 lbs. / sf |

| Panel Joints | 5/8" nominal (1/8" - 1" available) |

| Material Finish | Mill Steel - Naturally Weathering |

| Warranty | 1 year for MFG |

16GA Weathering Steel

Technical Information

| Material | 16GA | A606-4 Weathering Steel |

| System Depth | 1-1/4" nominal standard, up to 3" |

| Material Weight | ≈ 3 lbs. / sf |

| Panel Joints | 5/8" nominal (1/8" - 1" available) |

| Material Finish | Mill Steel - Naturally Weathering |

| Warranty | 1 year for MFG |

18GA Stainless Steel

Technical Information

| Material | 18 GA | 316 Stainless Steel |

| System Depth | 1-1/4" nominal standard, up to 3" |

| Material Weight | ≈ 3 lbs. / sf |

| Panel Joints | 5/8" nominal (1/8" - 1" available) |

| Material Finish | Polish, Brushed, Angel Hair, 2B |

| Warranty | 2 year for MFG |

Contractor Resources

-

Product Information

-

Details

-

Specifications

-

Color Charts

.png?width=300&name=select%20&%20lite%20technical%20product%20guide%20(1).png)

.jpg?width=750&name=2101521818087220494%20(1).jpg)

.png?width=300&name=premier%20technical%20product%20guide%20(2).png)

.png?width=300&name=ctf%20details%20(1).png)

.png?width=300&name=ws%20specs%20(1).png)

.png?width=300&name=Painted%20Aluminum%20(2).png)

.png?width=300&name=Nedzink%20(6).png)