Flat

Sleek, depth-free design.

Faster lead times

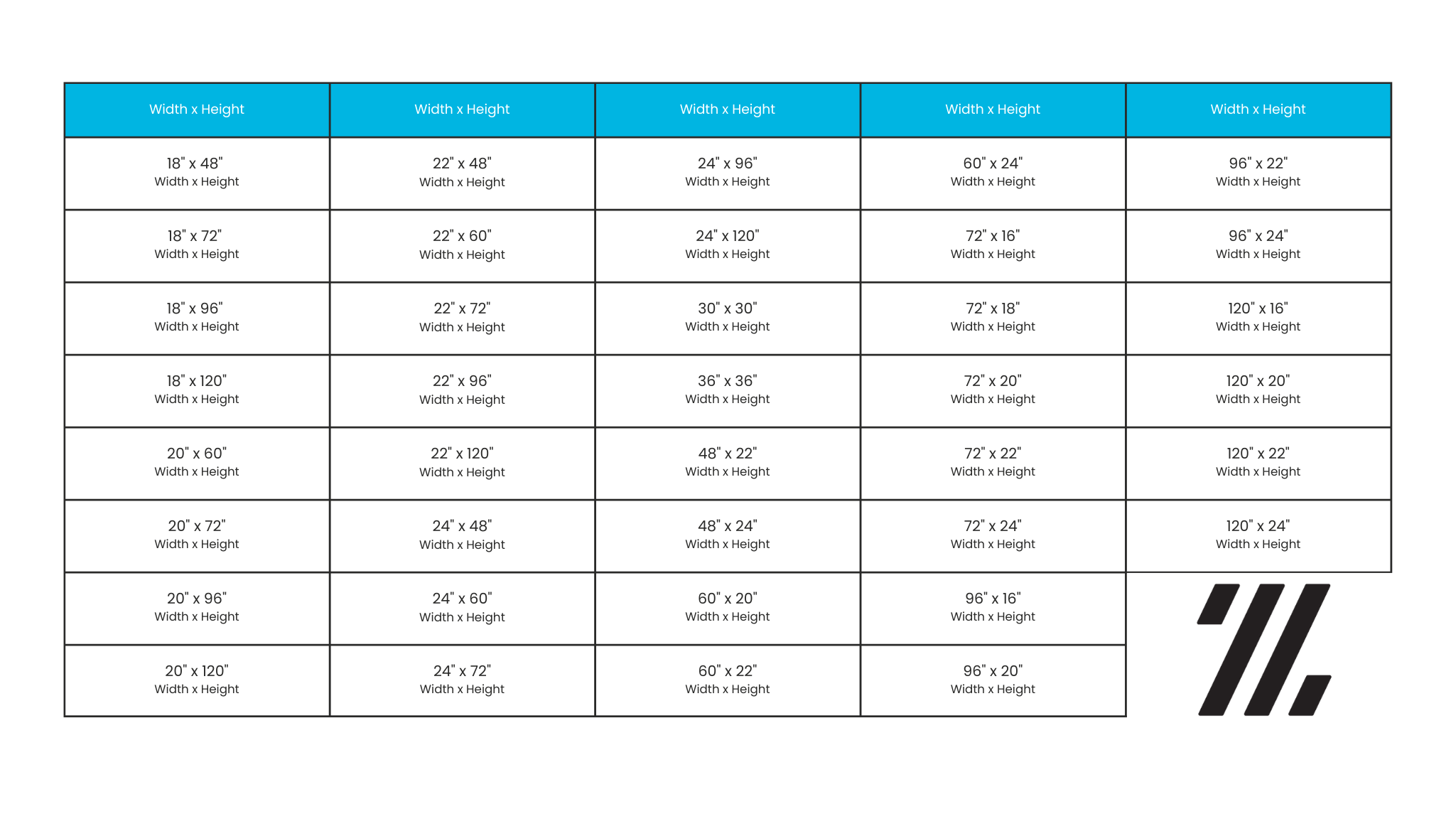

Origin Select offers premium performance without the premium price, thanks to a streamlined manufacturing process and targeted size options—perfect for projects that demand top-tier results while staying on budget.

Origin Select

%20(1).png?width=7500&name=1%20(1)%20(1).png)

%20(1).png?width=7500&name=4%20(1)%20(1).png)

Install the 2 piece J extrusion backpiece where needed.

Drill weep holes as need at the bottom.

%20(1).png?width=7500&name=3%20(1)%20(1).png)

%20(1).png?width=7500&name=7%20(1)%20(1).png)

Field trim panels as needed to accommodate site conditions.

Begin installation at the bottom left corner of the assembly.

%20(1).png?width=7500&name=11%20(1)%20(1).png)

%20(1).png?width=7500&name=13%20(2)%20(1).png)

%20(1).png?width=7500&name=14%20(2)%20(1).png)